BTR VSI®

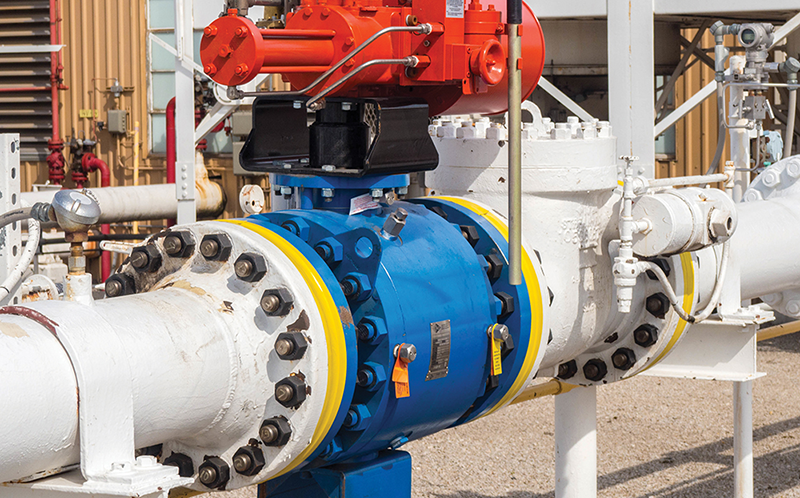

High-Pressure Valve Sealant Injection Equipment

BTR VSI® offers a streamlined range of high-pressure sealant injection equipment, perfect for handling our robust valve lubricants and sealants. Having a pump system with high capability is crucial to ensure smooth product injection into the valve, and our pumps are designed to meet that demand. To enhance precision and efficiency, we have developed customised stroke counters for pneumatic pump systems. These counters enable operators to accurately inject the right amount of sealant into the valve, ensuring proper lubrication and protection without waste. Our Sealant Injection Pumps are specially crafted to safely inject viscous sealants into highly pressurised valves. With a design tailored for demanding field conditions, they offer years of continuous service and have gained worldwide acclaim among industry professionals.