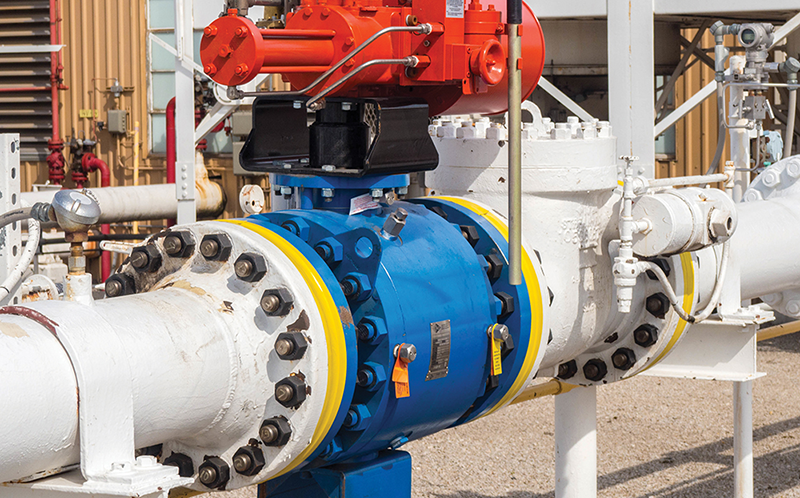

BTR VSI®

Online Valve Maintenance Case Studies

High quality valve cleaners, lubricants and sealants have been used around the world to reduce cost, control passing an prevent fugitive emissions.

High quality valve cleaners, lubricants and sealants have been used around the world to reduce cost, control passing an prevent fugitive emissions.

ADCO’s Bab Field, situated in Abu Dhabi, is a crucial onshore oil and gas field covering approximately 1200 sq.km. Its strategic location between Madinat Zayed and Marfa communities makes it significant to Abu Dhabi’s future.

Recognizing operational challenges, ADCO sought a viable solution and opted for high-performance Valve Lubricant. A field trial was conducted, injecting the lubricant into Gas Wells Bb-195, 373, and 466.

Following the injection of top-quality Valve Lubricant into the passing valves of the three wellheads, the passing ceased, and operators experienced smoother valve operation. The valves were monitored for two months, and the results from the trial were consistently positive. The same successful trials were replicated for two oil production wells, effectively stopping leaks and enhancing valve operation ease.

The harsh operating conditions in the Middle East, characterized by extreme temperatures and sand ingress, frequently cause valve component damage, leading to leaks, higher maintenance expenses, and non-production time (NPT).

ADNOC faced difficulties in ensuring sufficient valve integrity for the flow back stage of the drilling process. Maintaining valve integrity during flow back is critical to prevent potential well kicks. Engineers require confidence that flow back manifold valves can effectively control the flow back pressure during this stage.

Using information on valve condition, service history and problems the correct cleaner can be deployed to produce maximum effectiveness.

We would love to guide you to choose the best product for your needs.